Hyunsung TNC manufactures complex metal oxide targets - composed of Cd, Mg, Ba, Y, Cu, and Ox - based on superconducting compositions derived from the MEL Theory, optimized for high and room temperature superconductors and alloy metallic high temperature superconductors.

Unlike simple mixed powders, these targets are engineered with carefully controlled elemental ratios, taking into account each metal’s ionic reactivity, diffusion behavior, and oxidation characteristics.

Superconducting compositions designed from MEL Theory

High purity, high density, and uniform microstructure

Customizable dimensions

Full compatibility with CTLA process parameters

Hyunsung TNC holds the core intellectual property (IP) for superconductor design technologies built on the MEL theory, along with AI-powered composition design models.

We plan to provide this technology to academic institutions, industry partners, and research organizations through a structured IP licensing program.

Our IP licensing model goes beyond simple technology transfer - it aims to eliminate uncertainty in superconductor development and significantly reduce the total development cycle from composition design to experimentation and production.

Composition Design Engine License

Application-Specific Superconductor Design License

Co-development License

Using Experimental Data Integration

Platform Integration License

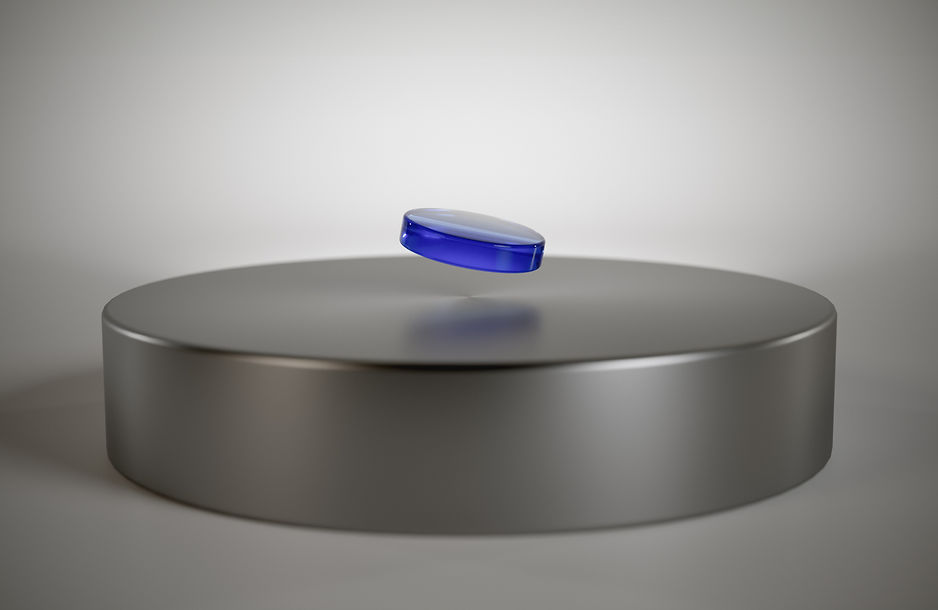

For research institutions and companies without direct access to target fabrication, Hyunsung TNC offers precision thin-film deposition services based on its proprietary CTLA (Circular Target Laser Ablation) system. Customers can simply specify the desired superconducting material composition, and Hyunsung TNC will produce ultra-uniform thin films (±0.5% compositional variation) using its in-house CTLA equipment.

The service also includes consulting support on substrate selection, deposition conditions, and post-annealing processes.

Deposition is available for materials such as Cd–XX–O, YBCO, REBCO, TBCO, and Cu–O–based systems,

with scalable options from prototype samples to small-batch production.